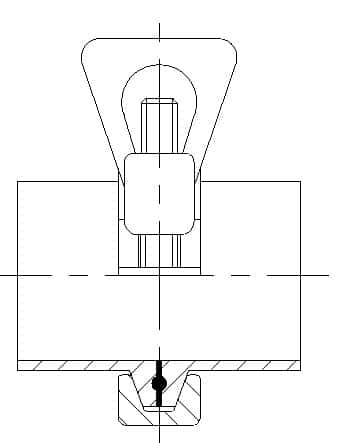

RACCORD CLAMP

Le CLAMP, qui est un standard utilisé lorsque la ligne de fabrication doit être souvent démontée.

- Obtenus à partir de pièces forgées ou taillées dans la masse pour les petits diamètres

- Fermeture rapide conforme aux normes 3-A

- Finition standard : polissage extérieur et satinage intérieur grain 150 (finissage LS) ; sur demande, polissage extérieur et intérieur grain 240 (finissage LL), polissage électrolytique grain 400 (finissage LE).

- Joints EPDM, silicone, PTFE, EDPM revêtus PTFE.

- Modèles de joint clamp standard, joint à lèvres, joint à enveloppe.

- Certifications des matériaux et tests de rugosité disponibles sur demande.

- Pour les autres articles conformes aux normes CLAMP, voir les informations techniques fournies dans les chapitres correspondants.

- Tous les raccords CLAMP, les robinets, les vannes à boule modèle 90, les vannes pneumatiques série 900, et les vannes à membrane sont réalisés en respectant scrupuleusement les critères et les tests imposés par les normes 3-A.

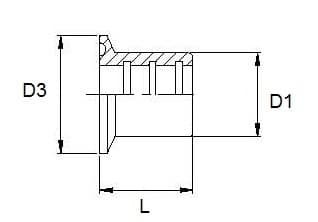

COLLET - FERRULE A SOUDER INOX 316L

| POUR TUBE ø | Norme | D3 | D2 | D1 | L |

| 2-4-6-8-10 | MICRO | 25 | - | - | 21 |

| 12 | MICRO | 25 | 10 | 12.6 | 21 |

| 13.5 | MICRO | 25 | 10.3 | 13.5 | 21 |

| 13.7 | ISO 1/4" | 34 | 10.3 | 13.5 | 21 |

| 16 | MICRO | 25 | 14 | 16 | 21 |

| 17 | MICRO | 25 | 14 | 17.2 | 21 |

| 17.2 | ISO 3/8" | 34 | 14 | 17.2 | 21 |

| 18 | MICRO | 25 | 16 | 18 | 21 |

| 18 | DIN | 34 | 16 | 18.6 | 28.6 |

| 21.3 | ISO 1/2" | 34 | 18.1 | 21.9 | 28.6 |

| 25.4 | SMS - OD | 50.5 | 22.6 | 25.6 | 28.6 |

| 26.9 | ISO 3/4" | 50.5 | 23.7 | 26.9 | 28.6 |

| 28 | DIN | 50.5 | 26 | 29 | 28.6 |

| 32 | 50.5 | 29.6 | 32.6 | 28.6 | |

| 33.7 | ISO 1" | 50.5 | 30.5 | 33.7 | 28.6 |

| 34 | DIN | 50.5 | 32 | 35 | 28.6 |

| 38 | SMS - OD | 50.5 | 35.6 | 38.6 | 28.6 |

| 40 | DIN | 50.5 | 38 | 41 | 28.6 |

| 42.4 | ISO 1"1/4 | 50.5 | 39.2 | 42.4 | 28.6 |

| 48.3 | ISO 1"1/2 | 64 | 45.1 | 48.3 | 28.6 |

| 51 | SMS - OD | 64 | 48.6 | 51.6 | 28.6 |

| 52 | DIN | 64 | 50 | 53 | 28.6 |

| 60.3 | ISO 2" | 77.5 | 56.3 | 60.3 | 28.6 |

| 63.5 | SMS - OD | 77.5 | 60.3 | 64.1 | 28.6 |

| 70 | DIN | 91 | 66 | 71 | 28.6 |

| 76.1 | ISO 2"1/2 | 91 | 72.9 | 76.7 | 28.6 |

| 85 | DIN | 106 | 81 | 86 | 28.6 |

| 88.9 | ISO 3" | 106 | 84.9 | 89.8 | 28.6 |

| 101.6 | DIN | 119 | 98.3 | 101.6 | 28.6 |

| 104 | SMS - OD | 119 | 100.5 | 106 | 28.6 |

| 114.3 | ISO 4" | 132 | 110.3 | 115.6 | 28.6 |

| 129 | METRIQUE | 155 | 125 | 130.5 | 28.6 |

| 139.7 | ISO 5" | 155 | 135.7 | 140.5 | 28.6 |

| 154 | METRIQUE | 183 | 150 | 155 | 28.6 |

| 168.3 | ISO 6" | 183 | 163.1 | 169 | 28.6 |

| 204 | METRIQUE | 233.5 | 200 | 205.5 | 28.6 |

| 219.1 | ISO 8" | 233.5 | 213.9 | 220.5 | 28.6 |

| 250 | METRIQUE | 270 | 246 | 252 | 35 |

| 254 | METRIQUE | 270 | 250 | 255.5 | 35 |

| 273 | ISO 10" | 289 | 269 | 274.5 | 35 |

| 306 | METRIQUE | 328 | 300 | 306 | 35 |

| 323.9 | ISO 12 " | 338 | 316 | 324 | 35 |

| 355.6 | ISO 14" | 370 | 350 | 356 | 35 |

| 402 | METRIQUE | 425 | 396 | 402 | 35 |

| 406.4 | ISO 16 " | 425 | 400 | 407 | 35 |

- Températures d’utilisation -40°C à + 120°C

- Pression maximum d’utilisation 7 bars, à titre indicatif, ceci en fonction des caractéristiques des produits véhiculés, comme composition chimique, température, temps de contact, pression, etc…

SOUS RÉSERVES DE FAISABILITÉ TECHNIQUE

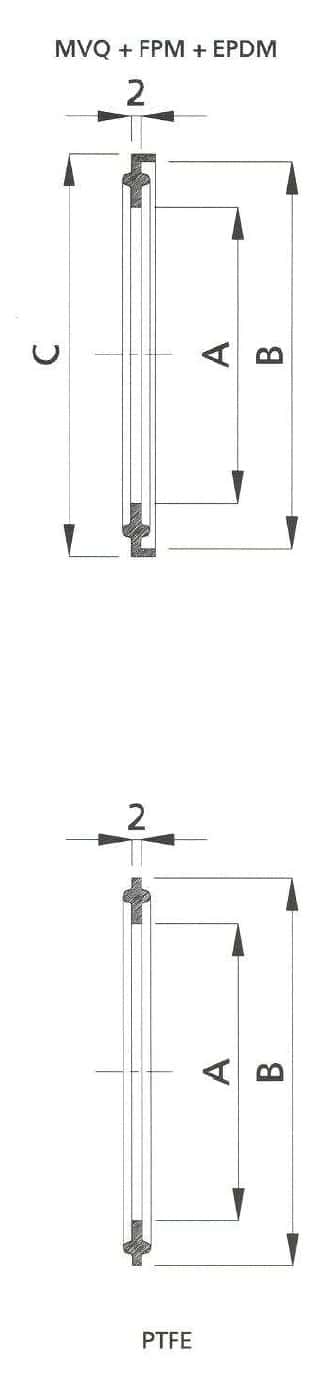

JOINTS CLAMP

| POUR COLLET ø | A | B | C | MVQ SILICONE | FPM VITON | PTFE TEFLON | EPDM . |

| 2-4-6-8-10 | 6 | 34 | 36.2 | ▄ | ▄ | ▄ | ▄ |

| 12 | 10.2 | 34 | 36.2 | ▄ | ▄ | ▄ | ▄ |

| 17.2 | 14.2 | 34 | 36.2 | ▄ | ▄ | ▄ | ▄ |

| 18 | 15.2 | 34 | 36.2 | ▄ | ▄ | ▄ | ▄ |

| 21.3 | 18.3 | 34 | 36.2 | ▄ | ▄ | ▄ | ▄ |

| 22 | 19.2 | 34 | 36.2 | ▄ | ▄ | ▄ | ▄ |

| 25.4 | 23 | 50 | 53 | ▄ | ▄ | ▄ | ▄ |

| 26.9 | 23.7 | 50 | 53 | ▄ | ▄ | ▄ | ▄ |

| 28 | 27 | 50 | 53 | ▄ | ▄ | ▄ | ▄ |

| 32 | 30 | 50 | 53 | ▄ | ▄ | ▄ | ▄ |

| 33.7 | 30.5 | 50 | 53 | ▄ | ▄ | ▄ | ▄ |

| 34 | 33 | 50 | 53 | ▄ | ▄ | ▄ | ▄ |

| 38 | 36 | 50 | 53 | ▄ | ▄ | ▄ | ▄ |

| 40 | 39 | 50 | 53 | ▄ | ▄ | ▄ | ▄ |

| 42.4 | 39.2 | 50 | 53 | ▄ | ▄ | ▄ | ▄ |

| 48.3 | 45.1 | 63.5 | 66.5 | ▄ | ▄ | ▄ | ▄ |

| 51 | 48.5 | 63.5 | 66.5 | ▄ | ▄ | ▄ | ▄ |

| 52 | 51 | 63.5 | 66.5 | ▄ | ▄ | ▄ | ▄ |

| 60.3 | 57.1 | 77 | 80 | ▄ | ▄ | ▄ | ▄ |

| 63.5 | 61.1 | 77 | 80 | ▄ | ▄ | ▄ | ▄ |

| 70 | 66.8 | 90.5 | 93.5 | ▄ | ▄ | ▄ | ▄ |

| 76.1 | 72.9 | 90.5 | 93.5 | ▄ | ▄ | ▄ | ▄ |

| 85 | 81.8 | 105.5 | 108.5 | ▄ | ▄ | ▄ | ▄ |

| 88.9 | 85.7 | 105.5 | 108.5 | ▄ | ▄ | ▄ | ▄ |

| 101.6 | 97.6 | 112.5 | 119 | ▄ | ▄ | ▄ | ▄ |

| 104 | 100.5 | 114.5 | 121.5 | ▄ | ▄ | ▄ | ▄ |

| 114.3 | 110.8 | 131.5 | 135.5 | ▄ | ▄ | ▄ | ▄ |

| 129 | 125 | 155 | 158.5 | ▄ | ▄ | ▄ | ▄ |

| 139.7 | 135.9 | 155 | 158.5 | ▄ | ▄ | ▄ | ▄ |

| 154 | 150 | 183 | 186.5 | ▄ | ▄ | ▄ | ▄ |

| 168.3 | 163.3 | 183 | 186.5 | ▄ | ▄ | ▄ | ▄ |

| 204 | 200 | 233 | 237 | ▄ | ▄ | ▄ | ▄ |

| 219.1 | 214.1 | 233 | 237 | ▄ | ▄ | ▄ | ▄ |

| 250 | 246 | 270 | ▄ | ||||

| 254 | 250 | 270 | ▄ | ||||

| 273 | 269 | 289 | 289 | ▄ | ▄ | ||

| 306 | 300 | 328 | ▄ | ||||

| 323.9 | 316 | 338 | 338 | ▄ | ▄ | ||

| 323.9 | 318 | 338 | ▄ | ||||

| 355.6 | 350 | 370 | ▄ | ||||

| 402 | 396 | 425 | ▄ | ||||

| 406.4 | 400 | 425 | ▄ |

SOUS RÉSERVES DE FAISABILITÉ TECHNIQUE

COLLIERS FORGES et EMBOUTIS pour CLAMP INOX 304L

| POUR COLLET ø | A mini | A micro | B | C | D |

| 2-4-6-8-10 | 40 | 27 | 26 | 36 | 42 |

| 12 | 40 | 27 | 26 | 36 | 42 |

| 17.2 | 40 | 27 | 26 | 36 | 42 |

| 18 | 40 | 27 | 26 | 36 | 42 |

| 21.3 | 40 | 27 | 26 | 36 | 42 |

| 22 | 40 | 27 | 26 | 36 | 42 |

| 25 | 62.5 | 38 | 68 | 60 | |

| 26.9 | 62.5 | 38 | 68 | 60 | |

| 28 | 62.5 | 38 | 68 | 60 | |

| 32 | 62.5 | 38 | 68 | 60 | |

| 33.7 | 62.5 | 38 | 68 | 60 | |

| 34 | 62.5 | 38 | 68 | 60 | |

| 38 | 62.5 | 38 | 68 | 60 | |

| 40 | 62.5 | 38 | 68 | 60 | |

| 42.4 | 62.5 | 38 | 68 | 60 | |

| 48.3 | 76 | 45 | 75 | 60 | |

| 51 | 76 | 45 | 75 | 60 | |

| 52 | 76 | 45 | 75 | 60 | |

| 60.3 | 89.5 | 52 | 82 | 60 | |

| 63.5 | 89.5 | 52 | 82 | 60 | |

| 70 | 103 | 59 | 88 | 60 | |

| 76.1 | 103 | 59 | 88 | 60 | |

| 85 | 118 | 69 | 96 | 60 | |

| 88.9 | 118 | 69 | 96 | 60 | |

| 104 | 131 | 75 | 105 | 60 | |

| 114.3 | 144 | 82 | 109 | 60 |

SOUS RÉSERVES DE FAISABILITÉ TECHNIQUE

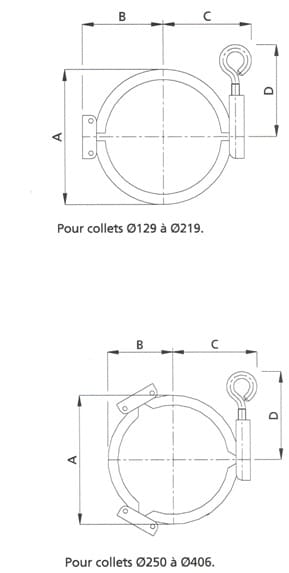

COLLIERS pour CLAMP

| POUR COLLET ø | A | B | C | D |

| 129 | 171 | 101 | 110 | 119 |

| 139.7 | 171 | 101 | 110 | 119 |

| 154 | 199 | 115 | 124 | 119 |

| 168.3 | 199 | 115 | 124 | 119 |

| 204 | 250 | 140 | 149 | 119 |

| 219.1 | 250 | 140 | 149 | 119 |

| 250 | 286 | 143 | 170 | 119 |

| 254 | 286 | 143 | 170 | 119 |

| 273 | 305 | 153 | 180 | 119 |

| 306 | 344 | 172 | 199 | 119 |

| 323.9 | 344 | 172 | 199 | 119 |

| 355.6 | 386 | 193 | 220 | 119 |

| 402 | 441 | 220 | 247 | 119 |

| 406.4 | 441 | 220 | 247 | 119 |

SOUS RÉSERVES DE FAISABILITÉ TECHNIQUE

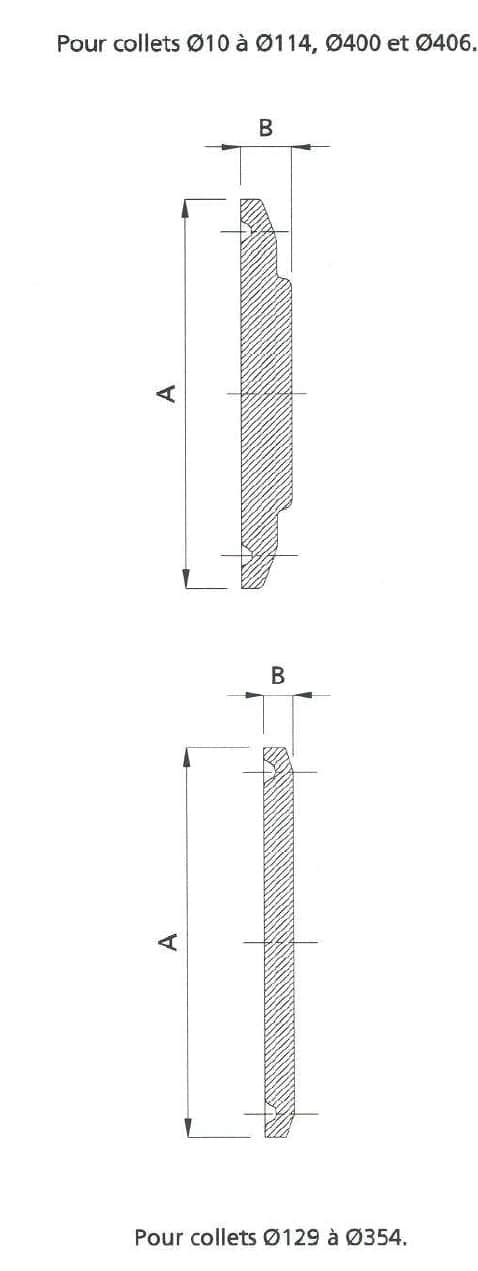

BOUCHONS pour CLAMP

| POUR COLLET ø | A | B |

| 10 | 34 | 4 |

| 12 | 34 | 4 |

| 17.2 | 34 | 4 |

| 18 | 34 | 4 |

| 21.3 | 34 | 4 |

| 22 | 34 | 4 |

| 25.4 | 51 | 4 |

| 26.9 | 51 | 7 |

| 28 | 51 | 7 |

| 32 | 51 | 7 |

| 33.7 | 51 | 7 |

| 34 | 51 | 7 |

| 38 | 51 | 7 |

| 40 | 51 | 7 |

| 42.4 | 51 | 7 |

| 48.3 | 64 | 7 |

| 51 | 64 | 7 |

| 52 | 64 | 7 |

| 60.3 | 77 | 7 |

| 63.5 | 77 | 7 |

| 70 | 91 | 7 |

| 76.1 | 91 | 7 |

| 85 | 106 | 7 |

| 88.9 | 106 | 7 |

| 104 | 119 | 7 |

| 114.3 | 132 | 7 |

| 129 | 155 | 8 |

| 139.7 | 155 | 8 |

| 154 | 183 | 8 |

| 168.3 | 183 | 8 |

| 204 | 233.5 | 8 |

| 219.1 | 233.5 | 8 |

| 250 | 270 | 8 |

| 254 | 270 | 8 |

| 273 | 289 | 8 |

| 306 | 328 | 8 |

| 323.9 | 338 | 8 |

| 355.6 | 370 | 10 |

| 402 | 425 | 14 |

| 406.4 | 425 | 14 |

ACCESSOIRES CLAMPES

| COUDE 90° ø | A | B | C | Poids gr |

| 12 1/2" | 88.8 | 25 | 19.4 | 90 |

| 19 3/4" | 88.8 | 34 | 15.7 | 120 |

| 25 1" | 50.8 | 50.5 | 22.1 | 170 |

| 38 1"1/2 | 69.9 | 50.5 | 34.8 | 200 |

| 51 2" | 88.9 | 64 | 47.5 | 370 |

| 63 2"1/2 | 108 | 77.5 | 60.2 | 500 |

| 76 3" | 127 | 91 | 72.9 | 910 |

| 101 4" | 168.3 | 119 | 97.4 | 1660 |

| COUDE 180° ø | A | B | C | Poids gr |

| 25 1" | 87.7 | 74 | 50.5 | 340 |

| 38 1"1/2 | 102.7 | 105 | 50.5 | 400 |

| 51 2" | 112.7 | 148 | 64 | 740 |

| 63 2"1/2 | 127.7 | 160 | 77.5 | 1000 |

| 76 3" | 142.7 | 167 | 91 | 1820 |

| 101 4" | 165.8 | 220 | 119 | 3320 |

| TE EGAL ø | A | B | C | Poids gr |

| 12 1/2" | 66.6 | 25 | 133.2 | 104 |

| 19 3/4" | 66.6 | 34 | 133.2 | 150 |

| 25 1" | 60.3 | 50.5 | 120.6 | 175 |

| 38 1"1/2 | 69.9 | 50.5 | 139.8 | 315 |

| 51 2" | 88.9 | 64 | 177.8 | 628 |

| 63 2"1/2 | 88.9 | 77.5 | 177.8 | 780 |

| 76 3" | 95.3 | 91 | 190.6 | 1135 |

| 101 4" | 114.3 | 119 | 228.6 | 1760 |

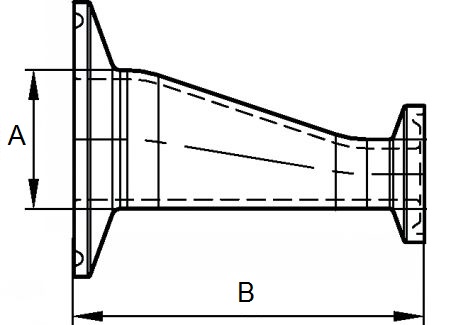

| REDUCTION CONCENTRIQUE ø | A | B | Poids gr |

| 3/4" -1/2" 19/12 | 50.8 | 25 | 80 |

| 1" - 3/4" 25/19 | 50.8 | 50.5 | 160 |

| 1 1/2" -1" 38/25 | 92.4 | 50.5 | 240 |

| 2"-1 1/2" 51/38 | 92.4 | 64 | 250 |

| 2 1/2"-2" 63/51 | 92.4 | 77.5 | 300 |

| 3"-2" 76/51 | 92.4 | 91 | 400 |

| 3"-2 1/2" 76/63 | 92.4 | 91 | 590 |

| 4" -3" 101/76 | 95.5 | 119 | 775 |

| REDUCTION EXCENTRIQUE ø | A | B | Poids gr |

| 3/4" -1/2" 19/12 | 50.8 | 25 | 80 |

| 1" - 3/4" 25/19 | 50.8 | 50.5 | 160 |

| 1 1/2" -1" 38/25 | 92.4 | 50.5 | 250 |

| 2"-1 1/2" 51/38 | 92.4 | 64 | 260 |

| 2 1/2"-2" 63/51 | 92.4 | 77.5 | 300 |

| 3"-2" 76/51 | 92.4 | 91 | 400 |

| 3"-2 1/2" 76/63 | 92.4 | 91 | 400 |

| 4" -3" 101/76 | 95.5 | 119 | 790 |